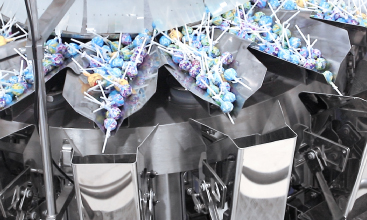

選別秤

選別秤工作原理

選別秤用於檢測產品的重量是否與目標重量相符,同時,自動選擇裝置會挑選出不合格的產品。我們的AC自動檢重秤型號適用於檢測易碎產品或未包裝好的產品,速度約為每分鐘50-90袋。

在許多行業和企業中,稱量產品是一個必不可少的步驟。準確的重量測量對於生產高質量的產品、確保客戶滿意度和促進產品成功至關重要。檢重秤系統是滿足所有這些需求的完美解決方案,因為它們可以輕鬆提供準確的重量測量。

選別秤

產品優勢

具備智能故障警報功能,因此設備故障可輕鬆檢測,使維護更為容易。同時,還配備了高速交錯排料功能,以防止物料堵塞。

還配備了自動供料功能,以其高精度和高標準而聞名。其所有零部件均符合國際標準,提高了整機零件的互換性。

底盤與中座一體焊接,大大增加了機器的強度。其操作介面可設定多種語言,在全球市場上具有很強的競爭力。支援多級重量校準,相容於多種不同材質的產品。

其精密的結構大大提高了進料速度,使物料能夠順暢流動。海川智能完善的模具製造技術,使得秤在使用時能更好的防止物料掉落,並能有效控制物料黏附問題,確保稱重精度。

FAQ

-

What types of products can a checkweigher handle?

A checkweigher can inspect a wide range of packaged and unpackaged items, including fresh meat, produce, seafood, bakery goods, ready meals, snacks, and industrial components. It ensures accurate weight control across trays, pouches, boxes, or loose items on high-speed lines.

-

How does a checkweigher maintain accuracy on high-speed production lines?

Checkweighers use high-sensitivity load cells and real-time signal processing to filter out vibration, product drift, and environmental noise. Dynamic compensation algorithms allow the system to maintain stable, precise measurements even under fast conveyor speeds.

-

How do I choose the right checkweigher for my production needs?

Selection depends on product size, weight range, packaging type, conveyor speed, and rejection requirements. Different checkweigher models support lightweight food packs, trays, boxes, or heavier industrial items, ensuring efficient integration into your production line.

-

Can a checkweigher be integrated with other inspection or packaging equipment?

Yes. Checkweighers can be integrated with upstream and downstream equipment such as metal detectors, labeling systems, and packaging machines. Through standard communication interfaces, production data can be transmitted to PLC or MES systems and further connected to ERP platforms, supporting data traceability, automated rejection, and efficient line operation.