金屬檢測器

金屬檢測器工作原理

金屬檢測器工作時,在其檢測區域內的中間發射線圈會產生一個電磁場,兩側對稱的接收線圈受到發射線圈交變磁場的作用,在其中分別產生感應電壓,兩接收線圈的感應電壓等值互相抵消,兩接收線圈處於平衡狀態。當有金屬通過時,檢測區內的電磁場發生改變,這一平衡狀態受到破壞,兩接收線圈產生微弱信號,並對該微弱信號進行放大和處理,最後輸出報警和排除的控制信號。

應用

- 廣泛適用於食品、醫藥、水產品、冷凍食品、化工產品、玩具、紡織等行業,可用於檢測產品或原料在生產加工、包裝過程中夾雜的金屬雜質。 如:鐵、不鏽鋼等非鐵磁性金屬,能有效提高產品安全係數,提升企業產品生產質量。

金屬檢測器

產品優勢

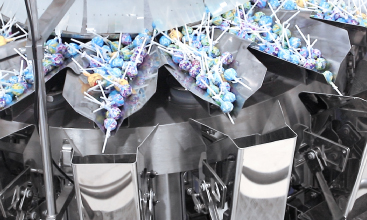

具備智能故障警報功能,因此設備故障可輕鬆檢測,使維護更為容易。同時,還配備了高速交錯排料功能,以防止物料堵塞。

還配備了自動供料功能,以其高精度和高標準而聞名。其所有零部件均符合國際標準,提高了整機零件的互換性。

底盤與中座一體焊接,大大增加了機器的強度。其操作界面可以設置為多種語言,使其在全球市場上具有很高的競爭力。

支持多級重量校準,並與許多不同材料製成的產品兼容。其精確的結構大大提高了給料速率,使材料流動更加順暢。海川智能 的完美模具製造技術確保了組合秤可以更好地防止材料掉落,並能有效控制材料黏附問題,確保稱重準確性。

The FAQ of Metal Detector

-

Why is metal detection important in food production?

A food metal detector is essential for preventing metal contamination in meat, seafood, bakery items, and packaged products. It protects consumers, reduces recall risks, and ensures manufacturers meet global food safety standards while maintaining product integrity on high-speed lines.

-

Can a food metal detector integrate with other inspection or packaging systems?

Yes. A metal detector for food can seamlessly integrate with checkweighers, rejectors, conveyors, and ERP/MES platforms. This enables automated rejection, centralized data tracking, and smoother HACCP workflows, enhancing overall production efficiency and quality control.

-

Why require metal detectors in production?

Many global standards recommend or require the use of a food metal detector to control physical hazards. Compliance strengthens export readiness, ensures traceability, and helps manufacturers meet retailer-specific audit requirements.

-

What is the difference between a metal detector and an X-ray inspection machine?

A food metal detector identifies metallic contaminants with high sensitivity, while an X-ray system can detect a broader range of foreign objects like bone, glass, and dense plastics. Metal detectors are cost-efficient for most applications, while X-ray is ideal for complex products.