失重秤

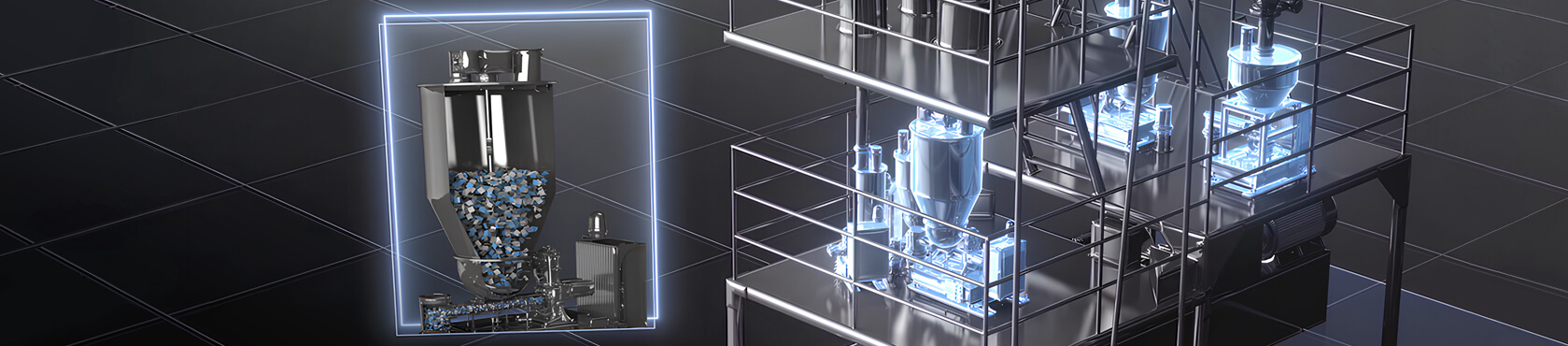

失重秤的工作原理

當失重秤系統運行時,料斗中的產品將首先被控制器從重量感測器中取樣,此時每單位時間的重量減少量即為實際給料量。然後,通過將實際給料量與設定值進行比較來獲取偏差值,然後通過閉環速度調節來調整減重給料器馬達的速度,從而達到準確的給料要求。

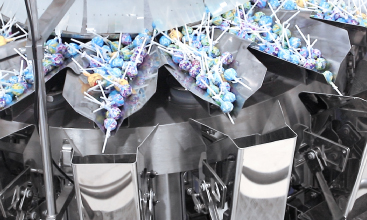

應用

- 大運輸能力,高精度的稱重減量給料系統

- 通過更換配件可以對應粉末/顆粒給料

- 螺杆部分可拆卸,組裝簡單,易於清潔

- 有相應的壓力和防爆、耐磨的內襯板配件

- 連續稱重減量給料器可用作前置給料裝置

- 稱重減量給料系統也可廣泛用於顆粒、粉末、碳酸鈣、滑石粉、樹脂薄膜粉、麵粉、澱粉等

- 提供非標準稱重減量給料器的設計服務

- 稱重減量給料系統可提供氣動平衡和除塵選項

- 專業準確的配料。配料控制系統具有強大的生產數據統計功能,為科學管理生產提供了強有力的保障

失重秤

產品優勢

具備智能故障警報功能,因此設備故障可輕鬆檢測,使維護更為容易。同時,還配備了高速交錯排料功能,以防止物料堵塞。

還配備了自動供料功能,以其高精度和高標準而聞名。其所有零部件均符合國際標準,提高了整機零件的互換性。

底盤與中置座的整合焊接大大提高了機器的強度。其操作界面可以設置為多種語言,這使其在全球市場上具有很高的競爭力。

它支援多階段的重量校準,並且兼容許多不同材質的產品。其精確的結構大大提高了給料速率,並使物料流動順暢。海川智能完善的模具製造技術確保了組合秤可以更好地防止物料掉落,並有效控制物料黏附問題,以保證稱重準確度。

The FAQ of Loss-In-Weight Feeder

-

What materials can a loss-in-weight feeder handle?

Loss-in-weight feeders can accurately dose a wide range of materials, including fine powders, cohesive blends, granules, flakes, liquids, and lightweight or compressible products. Different models—such as screw, vibratory, belt, or liquid types—ensure optimum performance based on material behavior.

-

How does a loss-in-weight feeder maintain feeding accuracy?

A loss-in-weight feeder measures weight reduction in real time and adjusts the feeding mechanism through closed-loop control. This ensures consistent dosing even when material density, flow characteristics, or environmental conditions change during continuous production.

-

How do I choose the right loss-in-weight feeder model?

Model selection depends on the material’s flowability, particle size, bulk density, and required dosing rate. Twin-screw types suit cohesive powders, vibratory models handle free-flowing materials, belt types fit fragile particles, while liquid models ensure stable fluid dosing.

-

Can loss-in-weight feeders support micro-volume or high-capacity processes?

Yes. The product range includes micro-flow feeders for ultra-low dosing and large-flow models for high-volume continuous production. Each configuration ensures stable, precise feeding tailored to applications in food, chemical, plastics, and specialty manufacturing.