線性秤

線性秤的工作原理

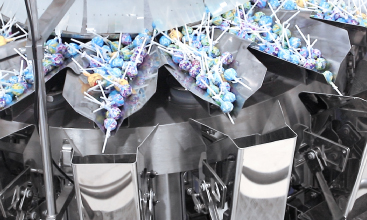

綫性秤用於完成定量包裝的計量工作,其計量過程包括自動喂料、計量、下料。其適用於包裝食品、醫藥、化工等行業的流動性差的顆粒狀商品,如花生、瓜子、味精、白糖、飼料、顆粒狀添加劑等。

自動化對於提高生產線效率至關重要——而我們的線性秤消除了手動稱量和填充的需求。我們的線性秤設計緊湊、快速且準確,專為高效稱量自由流動和半自由流動的食品和非食品物品而設計。

線性秤

產品優勢

具備智能故障警報功能,因此設備故障可輕鬆檢測,使維護更為容易。同時,還配備了高速交錯排料功能,以防止物料堵塞。

還配備了自動供料功能,以其高精度和高標準而聞名。其所有零部件均符合國際標準,提高了整機零件的互換性。

底盤與中座一體焊接,大大增加了機器的強度。其操作介面可設定多種語言,在全球市場上具有很強的競爭力。支援多級重量校準,相容於多種不同材質的產品。

其精密的結構大大提高了進料速度,使物料能夠順暢流動。海川智能完善的模具製造技術,使得秤在使用時能更好的防止物料掉落,並能有效控制物料黏附問題,確保稱重精度。

FAQ of Linear Weigher

-

What types of products can a linear weigher handle?

A linear weigher is ideal for free-flowing and semi-free-flowing granular commodities, such as grains, nuts, seeds, snacks and chemical granular additives. Its vibration-based feeding system ensures stable flow and accurate dosing across a wide range of materials.

-

How accurate is a linear weigher compared to manual weighing?

A linear weigher delivers significantly higher accuracy through load-cell feedback and controlled vibration feeding. This minimizes giveaway, improves consistency, and ensures precise portioning even in continuous, high-speed production environments.

-

Can a linear weigher be integrated into existing packaging lines?

Yes. The compact, modular design of a linear weigher allows seamless integration with form-fill-seal machines, conveyor systems, baggers, and automated packing equipment. It supports multi-head combinations for higher output and greater operational flexibility.

-

What maintenance is required for a linear weigher?

A linear weigher requires minimal maintenance thanks to its simple mechanical structure. Regular cleaning of contact surfaces, periodic inspection of load cells, and vibration tuning ensure long-term stability and reliable performance in demanding production conditions.