Linear Weigher

Linear Weigher Overview

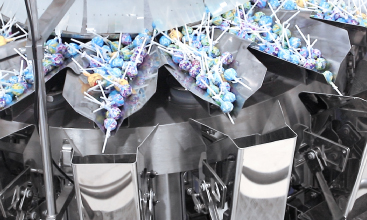

A linear weigher is an essential weighing solution for free-flowing and semi-free-flowing granule, delivering stable accuracy and faster dosing for food and industrial applications. Designed for automated packaging lines, each linear weigher improves filling efficiency, consistency, and overall production performance.

Linear Weigher

PRODUCT ADVANTAGES

High-Accuracy Weighing for Free-Flowing Products

Each linear weigher provides stable, high-precision dosing for grains, nuts, snacks, and other free-flowing products. Its refined load-cell control ensures consistent filling accuracy, reducing product giveaway and improving packaging efficiency.Smooth, Controlled Feeding for Semi-Free-Flowing Materials

The linear weigher is engineered to handle semi-free-flowing items like dried foods, pet food, and chemical granules. Its optimized vibration and discharge structure maintains steady product flow, preventing clogs and ensuring reliable portioning in continuous production.Compact, Modular Design for Easy Integration

With a compact footprint and modular construction, the linear weigher fits seamlessly into new or existing packaging lines. Its flexible configuration supports multi-head combinations, making it suitable for a wide range of production capacities and product types.Low Maintenance and Durable Performance

Built with durable materials and simplified mechanical components, each linear weigher minimizes downtime and maintenance requirements. Its user-friendly interface and robust structure make it ideal for long-term, stable operation in demanding industrial environments.FAQ of Linear Weigher

-

What types of products can a linear weigher handle?

A linear weigher is ideal for free-flowing and semi-free-flowing granular commodities, such as grains, nuts, seeds, snacks and chemical granular additives. Its vibration-based feeding system ensures stable flow and accurate dosing across a wide range of materials.

-

How accurate is a linear weigher compared to manual weighing?

A linear weigher delivers significantly higher accuracy through load-cell feedback and controlled vibration feeding. This minimizes giveaway, improves consistency, and ensures precise portioning even in continuous, high-speed production environments.

-

Can a linear weigher be integrated into existing packaging lines?

Yes. The compact, modular design of a linear weigher allows seamless integration with form-fill-seal machines, conveyor systems, baggers, and automated packing equipment. It supports multi-head combinations for higher output and greater operational flexibility.

-

What maintenance is required for a linear weigher?

A linear weigher requires minimal maintenance thanks to its simple mechanical structure. Regular cleaning of contact surfaces, periodic inspection of load cells, and vibration tuning ensure long-term stability and reliable performance in demanding production conditions.