Metal Detector

Product Description

A metal detector for food helps eliminate metal contaminants in dry bulk goods, grains, nuts, flour, spices, bakery items, bread, cereals, cheese. Engineered for high sensitivity and stable performance, it ensures compliance with global food safety standards and enhances overall HACCP-based quality control.

Metal Detector Working Principle

When metal detector is running, there will be an electromagnetic field generated from the middle sending wiring coil in the detecting area.The symmetric receiving wiring coil on both sides will have induced voltage under the use of alternating electromagnetic from sending wiring coils. The induced voltages from those two receiving wiring coils is equivalent and counteract with each other, two receiving wiring coils will be in equilibrium status.

When metal passes through, the electromagnetic field will change and the equilibrium status will be broken. The two receiving wiring coils will send out weak signal, which will be enlarged and treated in the system.Finally, it will send out alarm and rejecting signal.

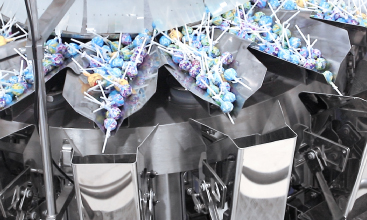

Application

It is widely used in industries of food,medicine,aquatic products,frozen products,chemical, toy and textile etc.It can be used to detect metal impurities inside product, raw material or packet during processing or packaging.

It can detect all types of metal, such as iron, stainless steel and Non-Fe. This can effectively ensure the product safety and improve the production quality in the company.

-

Food Processing Plants :

detecting metal contaminants in meat, nuts, confectionery, frozen foods, seasonings, dairy products, etc. -

Pharmaceutical Industry :

ensuring raw materials, medicines, and packaging are free from metal contamination. -

Seafood Processing Plants :

detecting metal in fish, shellfish, seaweed, and other seafood products. -

Frozen Food Plants :

inspecting frozen vegetables, frozen meat, frozen pastries, and similar products for metal. -

Chemical Industry :

detecting metal contaminants in chemical raw materials, plastic pellets, coatings, dyes, etc. -

Textile Factories :

ensuring textiles, garments, and home textiles are free from metal impurities. -

Toy Manufacturing :

ensuring toys and children’s products do not contain harmful metals.

Types of Metal Detector for Food Application

Food metal detection systems are available in several configurations to meet the diverse needs of modern food production. Conveyor food metal detectors are the most widely used, providing reliable inline inspection for packaged products, trays, and finished goods, making them essential in HACCP metal detection and end-of-line quality control. Free-fall or gravity-feed metal detectors support high-speed foreign body detection in food powders, grains, and granular ingredients moving through vertical pipelines with minimal product contact. Pipeline metal detectors for food processing are engineered for pumped, liquid, or viscous products—such as sauces, dairy, ground meat, and fillings—ensuring accurate contaminant detection under pressure.

Metal Detector

PRODUCT ADVANTAGES

High-Sensitivity Contaminant Detection

A food metal detector offers high-sensitivity detection for ferrous, non-ferrous, and stainless-steel contaminants, ensuring product safety across raw, frozen, and packaged foods. Its advanced signal processing technology minimizes false rejects while maintaining consistent inspection accuracy.Ensuring Food Safety and Reducing Product Recall Risks

Metal detectors enable food manufacturers to effectively remove metal contaminants during the product packaging process. This ensures compliance with global food safety standards and helps prevent costly product recalls caused by metal contamination.Stable Performance for Modern Production Lines

Designed for demanding food environments, a food metal detector delivers reliable performance under vibration, temperature changes, and high-speed conveyor conditions. Its robust construction reduces downtime and ensures consistent inspection quality in continuous operations.Seamless Integration with Packaging & Quality Systems

A food metal detector integrates easily with checkweighers, packaging machines, and ERP/MES systems to support automated rejection and data collection. This enhances quality control, improves line efficiency, and provides centralized oversight for multi-line food production facilities.The FAQ of Metal Detector

-

Why is metal detection important in food production?

A food metal detector is essential for preventing metal contamination in meat, seafood, bakery items, and packaged products. It protects consumers, reduces recall risks, and ensures manufacturers meet global food safety standards while maintaining product integrity on high-speed lines.

-

Can a food metal detector integrate with other inspection or packaging systems?

Yes. A metal detector for food can seamlessly integrate with checkweighers, rejectors, conveyors, and ERP/MES platforms. This enables automated rejection, centralized data tracking, and smoother HACCP workflows, enhancing overall production efficiency and quality control.

-

Why require metal detectors in production?

Many global standards recommend or require the use of a food metal detector to control physical hazards. Compliance strengthens export readiness, ensures traceability, and helps manufacturers meet retailer-specific audit requirements.

-

What is the difference between a metal detector and an X-ray inspection machine?

A food metal detector identifies metallic contaminants with high sensitivity, while an X-ray system can detect a broader range of foreign objects like bone, glass, and dense plastics. Metal detectors are cost-efficient for most applications, while X-ray is ideal for complex products.