Checkweighers

Product Description

High Dream check weighers are designed to deliver precise and efficient weight verification for a wide range of packaged products, including cartons, bags, cups, bottles, jars, and boxes. Tailored for industries such as food, personal care, and pharmaceuticals, these systems help ensure compliance with weight specifications while minimizing product giveaway—enhancing production efficiency and profitability.

With high-speed and stable performance, High Dream check weighers support various packaging formats and can be seamlessly integrated into existing production lines, making them an ideal solution for maintaining product quality and consistency.

Checkweigher Working Principle

Check weigher is used for detecting the weight of product whether match with the target weight, meanwhile auto-selecting device picks out the unqualified products. Our AC automatic checkweigher model is suitable for checking the fragile products or products without being capped, speed is around 50-90bag/min.

Weighing products is an essential step in many industries and businesses. Accurate weight measurement is crucial for producing high-quality products, ensuring customer satisfaction, and fostering product success. Check weigher systems are the perfect solution to all these needs, as they easily offer accurate weight measurement.

Checkweigher Integration for Smart Automation

- Easily integrates with metal detectors, labeling machines, and ERP/MES platforms

- Enables real-time data exchange and centralized production control

- Works with inspection systems to eliminate contaminated or non-compliant products

- Supports labeling for accurate product identification and traceability

- Facilitates the construction of smart, end-to-end automated production lines

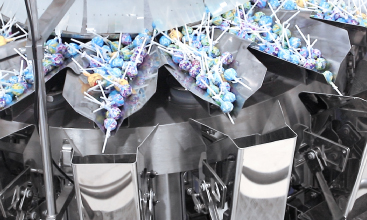

Application

Bakery & Snack Products

Bread loaves, rolls, pastries, muffins, packaged snacks.

Checkweighers provide reliable underweight and overweight detection for stable, high-volume bakery and snack products, ensuring declared weights without unnecessary system complexity.

Fresh Produce & Retail Packing

Apples, citrus, tomatoes, cucumbers, mixed produce trays.

For manually fed or low-speed produce lines, checkweighers help verify pack weights of variable items, reducing giveaway while maintaining simple and cost-effective operation.

Meat, Poultry & Seafood Processing

Beef cuts, chicken fillets, marinated portions, shrimp or fish trays.

Checkweighers are typically used at the end of processing lines to detect underweight or abnormal packs, acting as a final quality control step for fresh protein products.

Ready Meals, Central Kitchens & Delicatessen

Prepared meals, salads, deli trays, cheese portions, cold cuts.

In multi-SKU and small-batch environments, entry-level checkweighers support consistent portion verification with fast changeover and straightforward operation.[1]

Checkweighers

PRODUCT ADVANTAGES

Fast and Stable Digital Weighing. Highdream Checkweighers use advanced digital modules for high-speed, stable, and precise weight detection. The patented frame ensures consistent accuracy, even under dynamic production conditions.

User-Friendly Touchscreen Interface. Equipped with a 10.4" multilingual touchscreen, our Checkweigher offers intuitive operation, remote control support, and easy setup—boosting efficiency across diverse global production teams.

Easy Maintenance and Flexible Rejection. Designed with a quick-detach belt, the Checkweigher allows easy cleaning and tool-free maintenance. Multiple rejection options—air blow, side down, T-push—adapt to various package types and workflows.

Smart Data Handling and Integration. Each Checkweigher supports up to 99 product presets and offers USB/network export. Built for IoT, it enables traceable, real-time data collection for smarter quality control and factory automation.

FAQ

-

What types of products can a checkweigher handle?

A checkweigher can inspect a wide range of packaged and unpackaged items, including fresh meat, produce, seafood, bakery goods, ready meals, snacks, and industrial components. It ensures accurate weight control across trays, pouches, boxes, or loose items on high-speed lines.

-

How does a checkweigher maintain accuracy on high-speed production lines?

Checkweighers use high-sensitivity load cells and real-time signal processing to filter out vibration, product drift, and environmental noise. Dynamic compensation algorithms allow the system to maintain stable, precise measurements even under fast conveyor speeds.

-

How do I choose the right checkweigher for my production needs?

Selection depends on product size, weight range, packaging type, conveyor speed, and rejection requirements. Different checkweigher models support lightweight food packs, trays, boxes, or heavier industrial items, ensuring efficient integration into your production line.

-

Can a checkweigher be integrated with other inspection or packaging equipment?

Yes. Checkweighers can be integrated with upstream and downstream equipment such as metal detectors, labeling systems, and packaging machines. Through standard communication interfaces, production data can be transmitted to PLC or MES systems and further connected to ERP platforms, supporting data traceability, automated rejection, and efficient line operation.