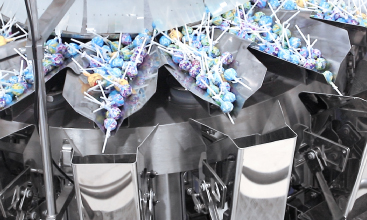

Weighing and labeling machine

Product Description

The weighing and labeling machine integrates high-precision weighing with fully automatic label application, delivering consistent accuracy for pre-packaged food products across fruits, vegetables, meat, and ready-to-eat items. As a key component in modern food weighing systems, it enhances pricing accuracy, and workflow efficiency. Designed for both food processing plants and retail operations, this automatic weighing and labeling solution supports high-speed production, reduces manual errors, and maintains reliable label quality for compliance and consumer confidence.

Weighing and labeling machine Working Principle

The Weighing and labeling machine is designed for fully automatic weighing and labeling of pre-packaged items, with a compact, space-saving body design and modular construction that can be better configured to meet the product and capacity requirements of retail, trade, and industrial.

Application

- Food packaging industry: Used for accurately weighing and labeling pre-packaged food items such as fruits, vegetables, meats, and dairy products.

- Retail sector: Implemented in retail stores for weighing and labeling various products before sale, ensuring accurate pricing and product information.

Weighing and labeling machine

PRODUCT ADVANTAGES

Fully automatic operation: Achieves complete automation of the weighing and labeling process, enhancing production efficiency.

Modular construction: Its modular structure allows for flexible configuration to meet the requirements of different products and capacities.

High-precision weighing: Utilizes advanced weighing technology to ensure accuracy and product quality.

User-friendly: Easy to operate and maintain, reducing labor costs and operational risks.

FAQ of Weighing and Labeling Machine

-

What is a weighing and labeling machine used for?

A weighing and labeling machine is designed to automatically weigh products and apply labels with pricing, barcodes, and product information. It helps food processors and retailers improve labeling accuracy and production efficiency for pre-packaged goods.

-

Is the weighing and labeling machine difficult to operate?

No, it’s user-friendly. The Weighing and labeling machine is designed for fully automatic weighing and labeling of pre-packaged items. After initial setup, just place pre-packaged items on the conveyor— the machine auto-completes weighing and labeling. Simplified maintenance (e.g., label paper replacement) with on-panel prompts reduces learning costs.

-

What industries commonly use a weighing and labeling machine?

This food weighing and labeling system is widely used in fruit and vegetable packing, meat and seafood processing, dairy products, ready-to-eat meals, and retail supermarkets. Its high-precision weighing and reliable labeling performance make it suitable for any pre-packaged food application.

-

How accurate is the automatic weighing and labeling process?

The weighing and labeling machine uses high-precision load cells and stable label applicators to ensure consistent accuracy in both weight measurement and label placement. It minimizes pricing errors, improves product presentation, and meets modern food labeling regulations.