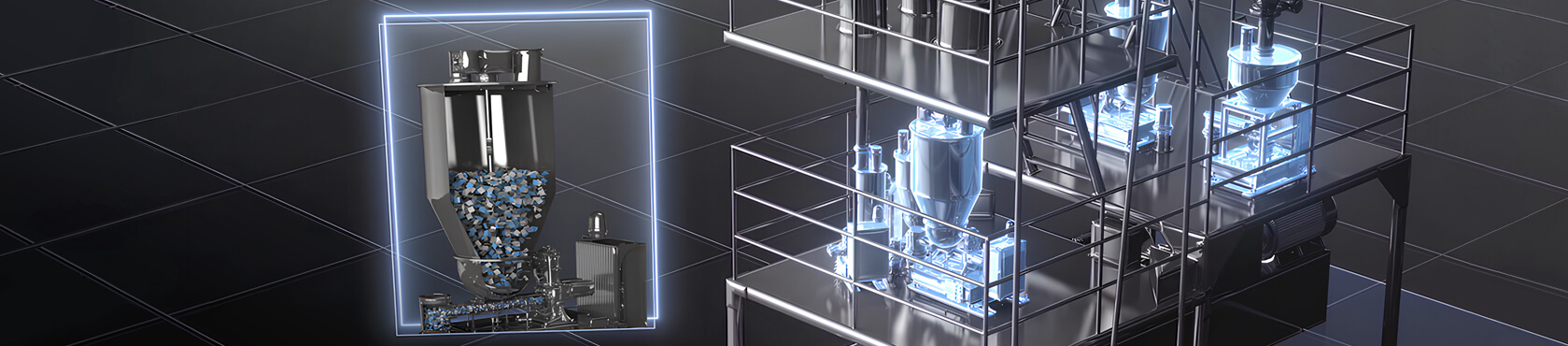

Loss-In-Weight Feeder

Product Description

The Loss-in-Weight Feeder is a precision gravimetric dosing system within the family of advanced gravimetric feeders, designed for continuous, stable, and highly accurate feeding of powders and particle feed. As a high-performance loss-in-weight feeder, this loss-in-weight design uses real-time weight control to ensure consistent material flow essential for modern industrial production.

Loss-in-Weight Feeder Working Principle

When the loss in weight feeder system is running, the product places in the hopper will be firstly sampled by the controller from the weight sensor, and at this time, the weight loss per unit time is the actual feeding quantity. Then, the deviation value will be obtained by comparing the actual feeding quantity with the set value, and then the speed of the loss in weight feeder motor will be adjusted by the closed-loop speed regulation so as to achieve the accurate feeding requirements.

Machine Features

- Large transport capacity, high precision loss-in-weight feeder system

- Through the replacement of accessories can correspond to the powder/particle feed

- Screw part of the decomposition, simple assembly, easy to clean

- There are corresponding specifications of pressure and explosion-proof, wear-resistant lining plate accessories

- The continuous loss in weight feeder can be used as the front feeding device

- The loss in weight feeder system can also be widely used for granule, powder, calcium carbonate, talc, resin film powder, flour, starch, etc

- Design Service is available to non-standard loss-in-weight feeders

- Pneumatic balance and dust removal options are available for the loss-in-weight feeder system

- Professional and accurate weighing ingredients. The ingredients control system has a powerful production data statistics function, so as provide users with a strong guarantee for the scientific management of production.

Application of Loss-in-Weight Feeders

The loss-in-weight feeder is suitable for dosing free-flowing powders, fine granules, and blended materials across food, chemical, and industrial production. Its stable and precise feeding performance makes it ideal for processes that require consistent, continuous material flow.

Loss-In-Weight Feeder

PRODUCT ADVANTAGES

Precision Feeding Accuracy

Highdream’s loss-in-weight feeder series delivers highly accurate, continuous dosing across various materials—from fine powders to micro-flow applications. With optimized screw, vibratory, and belt mechanisms, each unit ensures stable material flow essential for modern production lines.Versatile Configurations for All Material Types

From cohesive powders and lightweight flakes to liquids and colorants, the loss-in-weight feeder range includes twin-screw, single-screw, vibratory, liquid, and flexible-hopper models, allowing manufacturers to achieve precise feeding regardless of material characteristics.Stable Performance for Continuous Production

Engineered for industrial reliability, each loss-in-weight feeder provides smooth, uninterrupted feeding through strong screw engagement, controlled vibration, or gentle belt transport. These mechanisms help maintain consistent output even under demanding production conditions.Tailored Solutions for Specialized Applications

The loss-in-weight feeder lineup supports processes requiring micro-volume dosing, multi-ingredient blending, gentle handling, or high-capacity throughput. Its diversified designs enable precise, application-matched feeding performance for chemical, food, plastics, and specialty manufacturing.The FAQ of Loss-In-Weight Feeder

-

What materials can a loss-in-weight feeder handle?

Loss-in-weight feeders can accurately dose a wide range of materials, including fine powders, cohesive blends, granules, flakes, liquids, and lightweight or compressible products. Different models—such as screw, vibratory, belt, or liquid types—ensure optimum performance based on material behavior.

-

How does a loss-in-weight feeder maintain feeding accuracy?

A loss-in-weight feeder measures weight reduction in real time and adjusts the feeding mechanism through closed-loop control. This ensures consistent dosing even when material density, flow characteristics, or environmental conditions change during continuous production.

-

How do I choose the right loss-in-weight feeder model?

Model selection depends on the material’s flowability, particle size, bulk density, and required dosing rate. Twin-screw types suit cohesive powders, vibratory models handle free-flowing materials, belt types fit fragile particles, while liquid models ensure stable fluid dosing.

-

Can loss-in-weight feeders support micro-volume or high-capacity processes?

Yes. The product range includes micro-flow feeders for ultra-low dosing and large-flow models for high-volume continuous production. Each configuration ensures stable, precise feeding tailored to applications in food, chemical, plastics, and specialty manufacturing.