High Dream Conveyor Belt Metal Detector

Reliable Metal Detection. Safer Products. Stronger Brand.

Even the smallest piece of metal can cause massive problems—product recalls, production downtime, equipment damage, and, most critically, lost consumer trust. High Dream AC-RCB Conveyor Belt Metal Detector offers a reliable solution to detect and eliminate metallic impurities across various industries, including food, pharmaceuticals, chemicals, and textiles.

What is a Conveyor Belt Metal Detector?

A conveyor belt metal detector is an inline inspection system designed to identify and remove metallic contaminants from products during the production process. Utilizing electromagnetic induction technology, these detectors can sense the presence of various metals, ensuring that only contaminant-free products proceed down the line.

Types of Metallic Contaminants Detected:

-

Ferrous metals

: Iron and steel particles, often originating from machinery wear. -

Non-Ferrous metals

: Metals like aluminum and brass, which are non-magnetic but conductive. -

Stainless Steel (SUS)

: Common in food processing equipment; challenging to detect due to its low magnetic permeability.

Key Features of a High Dream Conveyor Belt Metal Detector

High Dream AC-RCB Conveyor Belt Metal Detector is meticulously engineered to ensure durability, hygiene, and seamless integration into various production lines. Its construction comprises several critical components:

Food-Grade PU Conveyor Belt:

- Customizable belt width (standard: 310 mm) to accommodate different product sizes and packaging formats

- Speed: 10–45 m/min | Max load: 5 kg

- Easy to clean and replace, designed for small to medium packaged goods

High-Sensitivity Detection Head:

- Tunnel size: 350mm × 175mm

-

Detects:

- Ferrous metals ≥ Ø0.8 mm

- Stainless steel ≥ Ø1.8 mm

- The detection head's design ensures minimal false positives while maintaining high sensitivity.

Automated Reject Mechanism:

- Optional reject devices: air blow, pusher, or flipper.

- Quickly removes contaminated products without stopping the line.

- Ensures only safe, high-quality products proceed to the next stage.

User-Friendly Control Panel:

- 7-inch color touchscreen with upgraded multilingual interface (6 languages).

- The intuitive design allows operators to easily configure the system, monitor operations, and access data.

Connectivity and Data Management:

- Equipped with USB and Internet ports, the AC-RCB model facilitates data output and remote control.

Structural Design:

- The machine's frame is constructed from stainless steel, offering robust support and resistance to corrosion.

Industry Applications

Key Food Industry Applications:

High Dream AC-RCB Metal Detector plays a vital role in food production, ensuring product safety and regulatory compliance. Its high sensitivity and multi-frequency capability make it ideal for:

-

Ready-to-eat meals, packaged meats, cheeses, and frozen foods

Detects and removes metal contaminants from products or worn equipment parts during processing—protecting both consumers and brand reputation. -

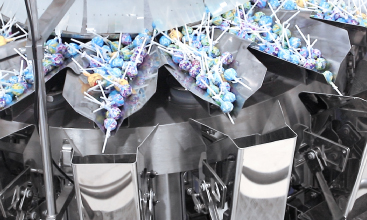

Bakery and confectionery products

Used in bread, cakes, biscuits, and chocolate lines to identify metal fragments from mixers, slicers, or conveyors—maintaining consistent product quality.

Other Industries Using Metal Detectors:

Beyond food processing, the AC-RCB model is widely adopted across various non-food sectors to ensure quality control and operational safety:

-

Pharmaceuticals

Detects metallic particles in capsules, tablets, and powder blends—ensuring product purity and compliance with GMP standards. -

Chemicals

Identifies metal contamination in powders, granules, and compound materials—preventing product rejection and equipment damage. -

Textiles

Used for needle detection in garment manufacturing and metal screening in fiber processing—safeguarding end-user safety and product integrity.

Why Is Metal Detection Crucial in Food and Packaging Industries?

Implementing metal detection systems is crucial for several reasons:

-

Regulatory Compliance

: Support complies with food safety standards around the world, such as HACCP, BRCGS, IFS, and FDA regulations. -

Consumer Trust

: Ensuring product safety fosters brand loyalty and protects reputation. -

Cost Avoidance

: Preventing recalls and potential legal actions saves significant financial resources. -

Product Integrity

: Maintaining high-quality standards by ensuring products are free from contaminants.

What Features Enhance High Dream Metal Detector Performance?

-

Detection Performance

The AC-RCB model boasts high sensitivity levels, capable of detecting ferrous particles as small as Ø0.8 mm and stainless steel particles as small as Ø1.8 mm. This ensures even minute contaminants are identified and removed.

-

Conveyor & Integration Compatibility

- Available with various conveyor widths and belt types to accommodate different packaging formats.

- Seamlessly integrates with check weighers and automated packing lines.

- Modular design allows for customization and future scalability.

-

Machine Design & User Interface

- Equipped with a 7-inch color touchscreen featuring an upgraded, multilingual interface.

- Offers 99 programs for memory.

- Self-learning system simplifies operation and reduces setup time.

- Multiple rejection mechanisms available, including air blowers, pushers, and flippers.

- USB and Ethernet ports facilitate data tracking and remote diagnostics.

- Designed for easy cleaning, with washdown-ready models available for hygiene-critical environments.

-

Selection Tips & After-Sales Support

We offer comprehensive after-sales support, including calibration, validation, and technical assistance.

Consider your production speed and required output, and match the detector's specifications with your product's size, weight, and product characteristics to select or customize the right model.

Choosing the Right Metal Detector for Your Line

Selecting the right detector depends on your product, speed, and production environment. Our team can help you evaluate your line and recommend the best-fit configuration.

Need help? We offer expert consultation, calibration, and technical support to ensure peak performance.

For more information or to request a consultation, visit our product page - AC-RCB Conveyor Belt Type Metal Detector.