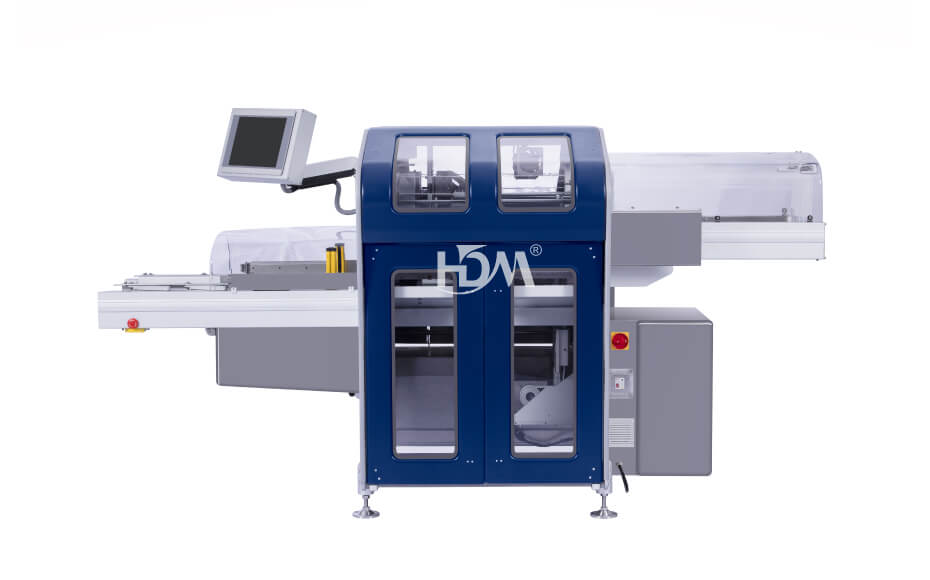

PRODUCT DESCRIPTION

Automatic food wrapping Machine is the ideal solution for highs peed food packaging, it can easily and efficiently package fresh food while extending the freshness and shelf life of the products. With fully automated operation, it reduces labor costs and increases production efficiency. It is widely used in greengrocer, mushroom farms, meat processing plants, supermarket processing centers.

- Easy Opera on : Large 12.1-inch touchscreen for intuitive operation; Low noise and more comfortable to use.

- Faster Speed: The electronic cam control system can improve packaging effciency; Maximum packaging speed up to 45 packs/minute.

- Flexible Packaging: Suitable for different tray sizes to meet diverse packaging needs.

- Separable Design: The separate conveyor belts allow for flexible adjustments based on your product's requirements, easy to install and dismantle.

The automatic wrapping solution is specifically designed to meet the market demand for high-speed packaging of fresh food. Highdream offers an integrated system comprising an automatic packaging machine and a weighing & labeling machine. High performance, simple operation, and easy cleaning make it an ideal equipment for fruit and vegetable processing centers.

Advantages of Food Wrapping

Proper food wrapping plays a crucial role in maintaining product quality from production to point-of-sale. An automated wrapping process ensures consistency, hygiene, and market-ready presentation. Key advantages include:

- Extended Freshness: Prevents moisture loss and reduces exposure to air, helping fruits, vegetables, and fresh meats stay fresh longer.

- Improved Hygiene Protection: Creates a clean, sealed barrier that minimizes contamination during handling and transport.

- Stronger Visual Appeal: Tight, transparent wrapping enhances product visibility and provides a professional, retail-ready appearance.

- Consistent Portioning: Ensures uniform tray coverage and stable packaging quality across high-volume production.

- Reduced Food Waste: Slows down oxidation and dehydration, allowing retailers to maintain better inventory control.

- Better Handling & Transport: Secured wrapping stabilizes items on trays, preventing spills, tears, or shape deformation during delivery.

Available Wrapping Film

Our automatic wrapping system is compatible with most commercially available stretch films on the market, offering excellent flexibility for diverse food applications. Whether using standard, high-stretch, or eco-friendly film, the system ensures stable, secure, and visually consistent packaging.

APPLICATION

- Greengrocers : apples, oranges, tomatoes, cucumbers, bell peppers

- Meat processing plants : beef steaks, pork chops, chicken fillets, sausage portions

- Supermarket processing centres : fresh mushrooms, ready-to-cook meals, fresh-cut vegetable trays, fruit snack packs, mixed salads

- Seafood counters : salmon fillets, shrimp trays, squid rings, shellfish portions

- Delicatessen sections : cheese portions, cold cut trays, sandwich packs, antipasti selections

- Bakeries and patisseries : bread loaves, croissant packs, muffin trays, pastry assortments

SPECIFICATION

| ltem | Automatic Food Wrapping Machine |

| Model | KW-6F-A45A |

| Monitor | 12.1 inch touch screen |

| Max. Packing Speed | 45 bag/min |

| Max. Weight | 3kg |

| Tray Size |

Length:120-320mm Width: 120-230mm Height: 10-160mm |

| Wrapping film width | 330mm-550mm |

| Power | 220V-240V 50Hz/60hz |

| Humidity | 35%-80% (no condensation around) |